Relays in Electric Switches

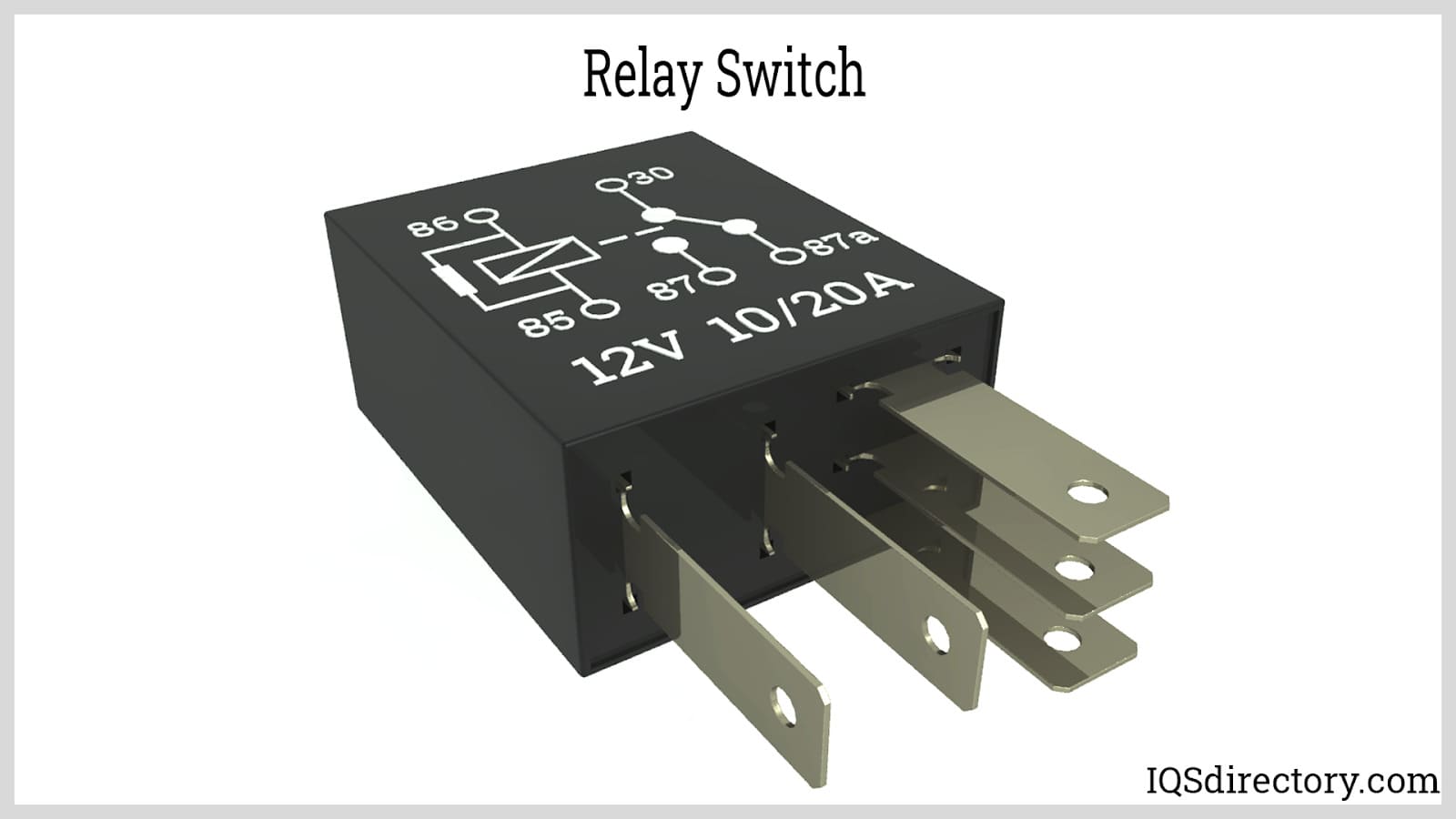

Relays are electrical constructions used when it is necessary to control a circuit using an independent power signal. The latter is often a low-power one. Briefly explained, a relay is a switch that is operated electrically.

An electromagnetic coil has been the basis of the traditional relay switch. An electrical signal would energize the coil to attract a metal contact placed in a particular arrangement. On being attracted, the metal contact moves, making or breaking a certain contact in the process. There usually is a mechanism to restore the contact to its normal position (that is, the de-energized state) once the attraction from the coil discontinues. The metal conduct remains attracted for as long as the coil is energized. In such an application, the relay would work as a momentary switch.

The latching relay is a variant of the switch described above and works more like a maintained switch. It usually takes signals of opposite polarity to open and close the circuit. The absence of power does not function like an instruction (it does not affect the controlled switch regardless of the state the latter might be in). These are used in cases where the controlled circuit needs both states for significant amounts of time each – so that the coil would not need power to maintain any one state.

In an electrical power supply, relays are used to open and/or close circuit breakers. Telecommunication systems made extensive use of electromagnetic switches until the not-so-distant past in applications like analog switching. Other applications are in railway signaling and transceiver selection.

Solid state relays are the electronic version of the electromagnetic relay. They make use of semiconductor components to achieve control of isolated circuits. An example is an optocoupler, which couples a light emitting diode and a photodiode.

Actuator Mechanisms in Electric Switches

Actuator mechanisms on a switch turn a circuit on and off manually. Examples of actuator mechanisms can be found in:

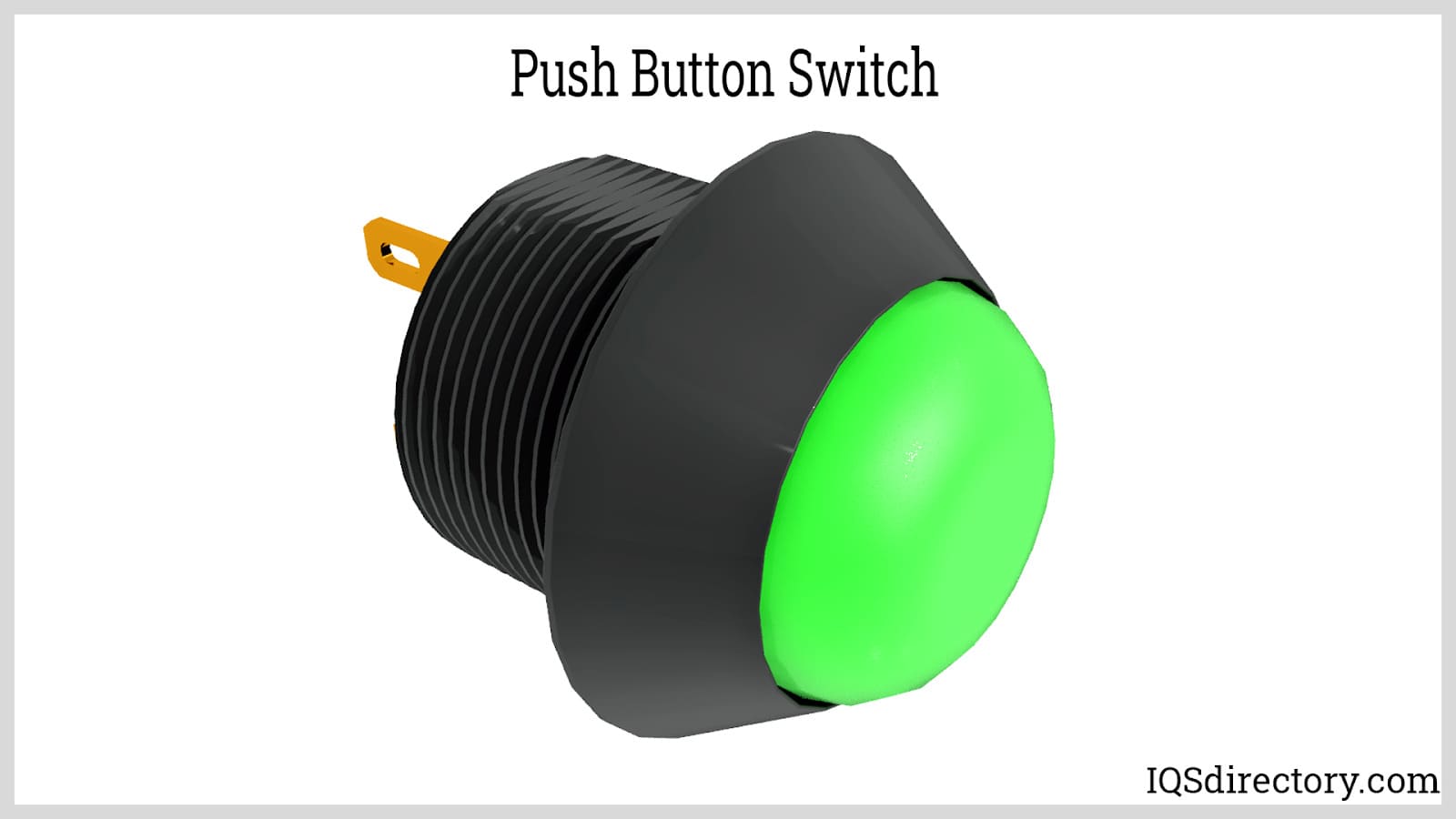

Push Button Switches

These switches come in the form of a button or a similar key. They can either be a maintained or momentary switch. The push button is the most common type of momentary switch. A normally closed push button switch is often called the push to break, and a normally open push button switch is often called the push to make a switch. The maintained push button switch is attached to a mechanism that alternately holds and releases with consecutive pushes.

Push buttons are usually two-state switches. Though it is technically feasible to have more than two states with a push button mechanism, this is not a popular choice.

Rocker Switches

These switches are so named because of how they move – in a rocking motion. A rocker switch has two main parts: a moving part that makes the back-and-forth rocking motion and a fixed part relative to which the rocking motionis made. The switch stays at either of the two extreme ends of the rocking motion, one of which is an on: ‘on‘ and ‘off‘. A rocker switch is the most common wall-mounted switch, particularly for domestic purposes. They can also be mounted to the particular device on which the power supply is to be controlled. For the latter application, however, they compete with maintained push button switches.

As the rocking motion implies, moving one end in one direction moves the opposite end in the reverse direction. Such movements are achieved by simply pressing the desired end. The rocking component on the switch is attached to a contact, so rocking in one direction closes a connection, and rocking in the reverse direction opens it.

Rotary Switches

This switch is most commonly used where more than two states, or anything more than a simple on and off, is required. The name ‘rotary‘ refers to how the states are selected rather than implying any number of states. Most applications with two states make use of rocker and push button switches.

A knob, or an equivalent component, rotates about an axis to move a contact around a circular array of connectors, alternately connecting them in the process. The rotation can be either smooth or stepped. It can have a definitive number of states or have an ‘off‘ state and a continuously varying ‘on‘ state. Rotary switches are usually maintained switches. They can be wall-mounted, particularly for industrial machinery, or mounted to the respective devices such as an electric oven.

Another common example of a rotary switch is the traditional key and socket car ignition switch.

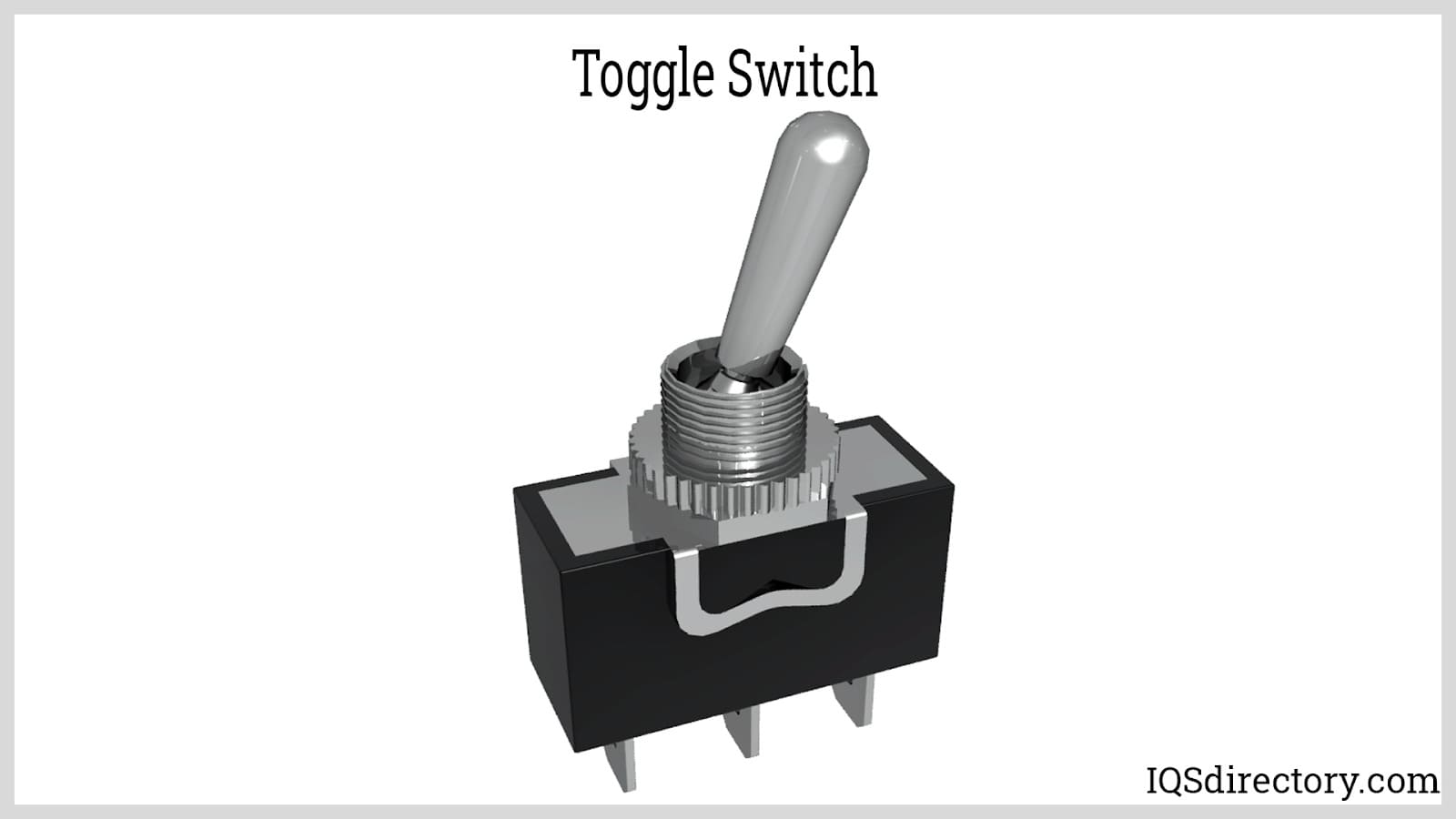

Toggle Switches

This kind of switch uses a lever to change the state of a connection. It is practicable as either a momentary or maintained switch. It is usually a two-state switch. The toggle switch is the most common type of actuation for household circuit breakers. Compared to other electrical switches, they can have high switching speeds.

Slide Switch

In this switch, a slide is moved from one position to another, moving a contact and changing the states of the connection. This is often a two-state switch, but it is practicable in more than two states. It is the most viable alternative to a rotary switch, though the latter remains preferable in most multi-state applications.

The motion of the slider can be smooth or stepped.

Connectors and Contactors in Electric Switches

A contactor is a component of an electrical circuit, particularly a switch. Its purpose is to make and break contact. The circuit is closed when the contactors are in contact and open when they are not. Such making and breaking of contact provides a means to control the flow of electrons – and therefore electrical power and signals – in a circuit.

Contactors are usually made up of metals, though any conductive material can be used.

The following materials are often used in the manufacture of contactors.

Copper and Copper Alloys

Copper is a very good conductor of electricity (and heat), with its conductivity being behind only that of silver. A common copper alloy used in the making of contactors is brass.

Silver and Silver Alloys

Silver is a good conductor of electricity, probably the best, in addition, silver and its alloys have good oxidation resistance.

Gold and Gold Alloys

Gold is also a good conductor, with its conductivity behind only copper and silver. Its resistance to corrosion is also high. However, amongst switch contactors, those made of gold are not very common because of the (un)availability of gold and its cost.

Platinum Group Metals

Platinum is possibly the most expensive material (per unit weight) used in circuitry. The cost becomes more apparent given that volume is often more important than weight, and platinum has a particularly high specific weight.

For a given material, the electrical resistance is dependent, in part, on the spatial dimensions of the conductors and not necessarily on the weight. It may also be noted, however, that mass also depends on spatial dimensions. It follows that there may be a correlation between weight and resistance, but never a dependency.

Carbon as a Conductor

Carbon is a non-metal but a conductor nonetheless (in some of its forms). It does not compare well with metals and is mainly used in experimentation and recreational applications. However, there are a few specialized industrial applications.

Other Metals

Most metals can be conductors and are used in various applications. They may be used where resistance may not be a very significant consideration.

These metals include:

- Chromium alloys

- Steel alloys